Exploring CNC and Laser Cutting Services in Toronto and Across Canada

In today’s manufacturing landscape, precision and efficiency are paramount, making CNC (Computer Numerical Control) and laser cutting technologies indispensable. These technologies not only streamline production processes but also ensure accuracy and versatility in material handling.

Let’s delve into CNC Toronto and laser cutting services available in Toronto and their broader applications across Canada.

Understanding CNC and Laser Cutting

CNC machines use computerized controls to execute intricate cutting, milling, and drilling tasks with high precision. These machines are crucial in various industries, including aerospace, automotive, and electronics, due to their ability to replicate designs with consistency and speed.

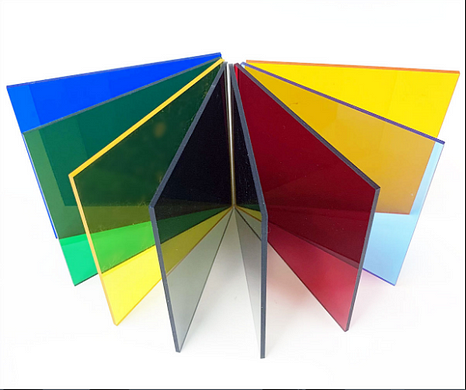

On the other hand, laser cutting utilizes a focused laser beam to cut through materials such as metal, wood, plastic, and glass.

This method is valued for its ability to achieve intricate designs without physical contact, resulting in clean edges and minimal material wastage.

CNC Laser Cutting Machines in Canada

Canada, including cities like Toronto, has seen a rise in demand for laser cutting in Toronto machines due to their efficiency and versatility. These machines are capable of handling a wide range of materials and thicknesses, making them ideal for both small-scale prototypes and large-scale production runs.

Laser Cutting in Toronto

Toronto, as a hub of industrial and technological innovation, boasts numerous facilities offering laser cutting services. These services cater to diverse industries, from signage and advertising to automotive parts manufacturing.

The precision and flexibility of laser cutting machines in Toronto ensure that businesses can meet stringent design requirements and tight deadlines effectively.

FAQs About CNC and Laser Cutting Services

1. What materials can be cut using CNC laser cutting machines?

CNC laser cutting machines can cut materials such as stainless steel, aluminum, carbon steel, acrylic (including plexiglass), wood, and various plastics with exceptional precision for plexiglass in Calgary.

2. What are the advantages of CNC laser cutting over traditional methods?

CNC laser cutting offers advantages such as higher precision, faster production speeds, reduced material waste, and the ability to cut complex shapes without the need for tooling changes.

3. How can businesses benefit from CNC and laser cutting services?

Businesses can benefit from these services by reducing production costs, improving product quality, accelerating time-to-market, and enhancing overall operational efficiency.

Plexiglass in Calgary from Plastics Source

Plastics Source, based in Calgary, is a leading supplier of plexiglass and other plastic materials across Canada. They provide high-quality plexiglass sheets that are ideal for various applications, including laser cutting. Whether you’re in Toronto, Vancouver, or anywhere in between, Plastics Source ensures reliable delivery and exceptional customer service.

Conclusion

In conclusion, CNC and laser cutting technologies are integral to modern manufacturing processes in Toronto and throughout Canada. Whether you’re looking for precise metal components or intricate acrylic designs, these technologies offer unmatched versatility and efficiency.

As industries continue to evolve, the demand for advanced cutting solutions provided by CNC and laser cutting machines will only grow, driving innovation and excellence across the manufacturing sector.

Comments

Post a Comment